A paper presented at SPE’s Artificial Lift Conference examines the range of artificial lift solutions for horizontal and multi-stage wells and the advantages of hydraulic jet pumps.

Abstract

At some point during production, most wells experience a drop in reservoir pressure that hinders production. This requires an artificial lift system to decrease or draw-down the pressure within the reservoir, in order to encourage more production to the surface. Selecting the proper artificial lift method is critical to the performance and profitability of today’s unconventional wells. This presentation will examine the range of artificial lift solutions available for horizontal and multi-stage wells, and discuss the advantages of hydraulic jet pumps versus rod pumps, electronic submersible pumps, and gas lift systems. A review of typical producing Permian Basin and Eagle Ford sites will show that the efficiency, versatility and reliability of hydraulic jet pumps can provide unmatched advantages when addressing the artificial lift challenges presented by unconventional, horizontal, multi-stage wells.

Introduction

At some point during production, most wells experience a drop in reservoir pressure that hinders production. This requires an artificial lift system to increase pressure within the reservoir, in order to encourage more production to the surface. A variety of artificial lift options are available to operators in order to recover more production. These include rod pumps, electric submersible pumps (ESPs), gas lift systems and hydraulic jet pumps. Selecting the proper artificial lift method is critical to the performance and profitability of today’s unconventional wells.

Rod pumps have long been a de facto standard for artificial lift in many onshore applications, due to their low upfront installation costs, operating efficiency and ability to provide operating information. On the downside, due to operational characteristics, rod pumps can be limited in their ability to encourage a well’s full production potential, and are not designed to optimize production in applications featuring rapid rate decline. In unconventional wells, which typically feature long laterals (and multiple frac stages per lateral), unique demands are placed on the sucker rods employed by rod pumps, which can lead to frequent fatigue failures requiring replacement of the pumps, rods and tubing. Early in a well’s rod lift application, several workovers per year can be required, at an average cost of around $90,000 per workover and repair. Compared to rod pumps, electric submersible pumps (ESPs) offer a number of design and operational advantages, including reliable operation in low-flow ranges, and fewer operational issues relating to gas, solids and deposits. In spite of these advantages, ESPs also have a number of operating challenges in unconventional applications. As a result of high sand and solid contents, run times can be compromised, and performance can be degraded when pumping viscous fluids or high gas-to-liquid ratio mixtures. What’s more, although ESP systems can operate at 0 to 90 degree inclinations, their application is restricted by the well curvature during deployment and landing. Workover and repair costs for ESPs are typically in the $150,000 range.

Gas lift systems are designed to recirculate lift gas, compressing low-pressure gas from the production separator, then reinjecting it into the well to lift the fluids from the reservoir. The distribution system must be large enough so that minimal pressure is lost between the compressor and the wellhead, and well casing must be able to withstand lift pressure. Gas lift operations can be difficult to operate in small, closed systems featuring limited gas-storage capacities, and are generally not efficient in lifting small fields or leases. Difficulty in lifting emulsions and viscous crudes, problems with dirty surface lines, safety problems with high pressure gas, and the inability to effectively produce deep wells to abandonment, are some of the challenges typical of gas lift operations. (Petrowiki/SPE)

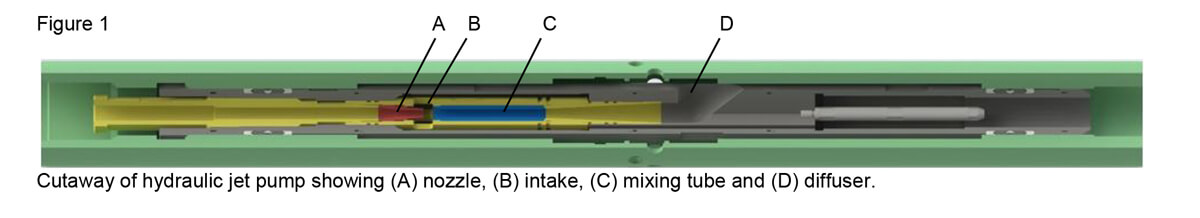

Hydraulic jet pumps, once limited to use on problem wells and frac flowback operations, are now taking priority as the artificial lift method of choice in unconventional wells. Hydraulic jet pumps function according to the Venturi effect, utilizing the momentum of one fluid to move another. This drawdown is what brings formation fluids into the jet pump and to the surface. The hydraulic jet pump consists of a nozzle, intake, mixing tube and diffuser, with a design that can be tailored to vertical, horizontal or deviated wells. (Figure 1) Maintenance and optimization of hydraulic jet pumps can be performed without the need for wireline or workover unit.

Statement of Theory

In unconventional wells exhibiting long laterals, tight turns, and high solids and gas production, hydraulic jet pumps can provide the most effective and reliable artificial lift performance, when compared to rod pumps, electric submersible pumps and gas lift systems.

Description and Application of Equipment and Processes

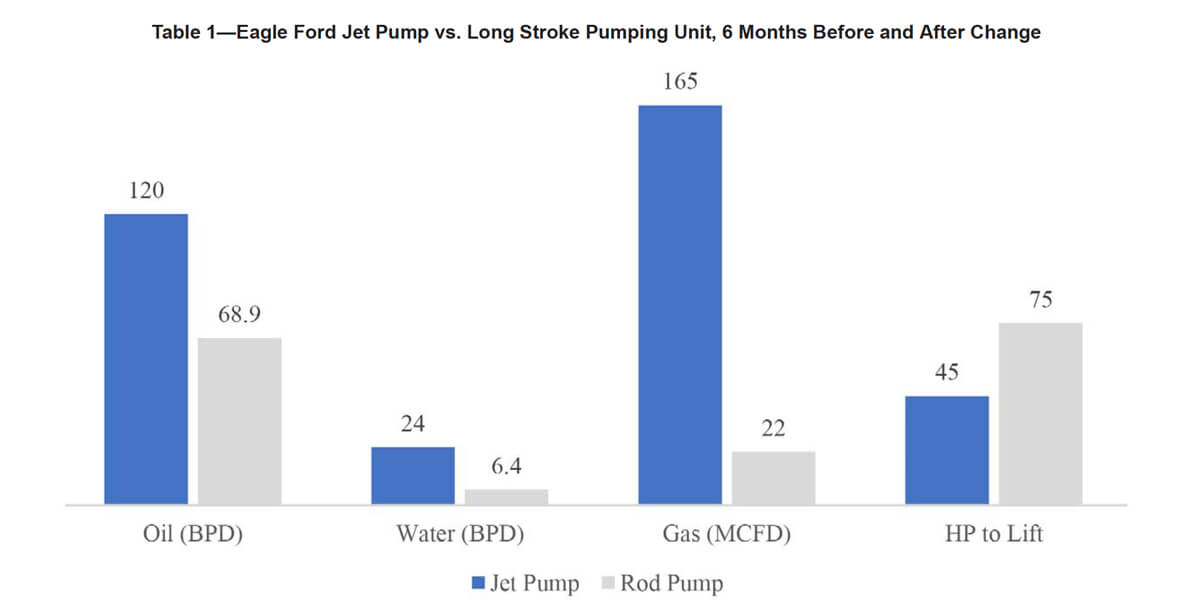

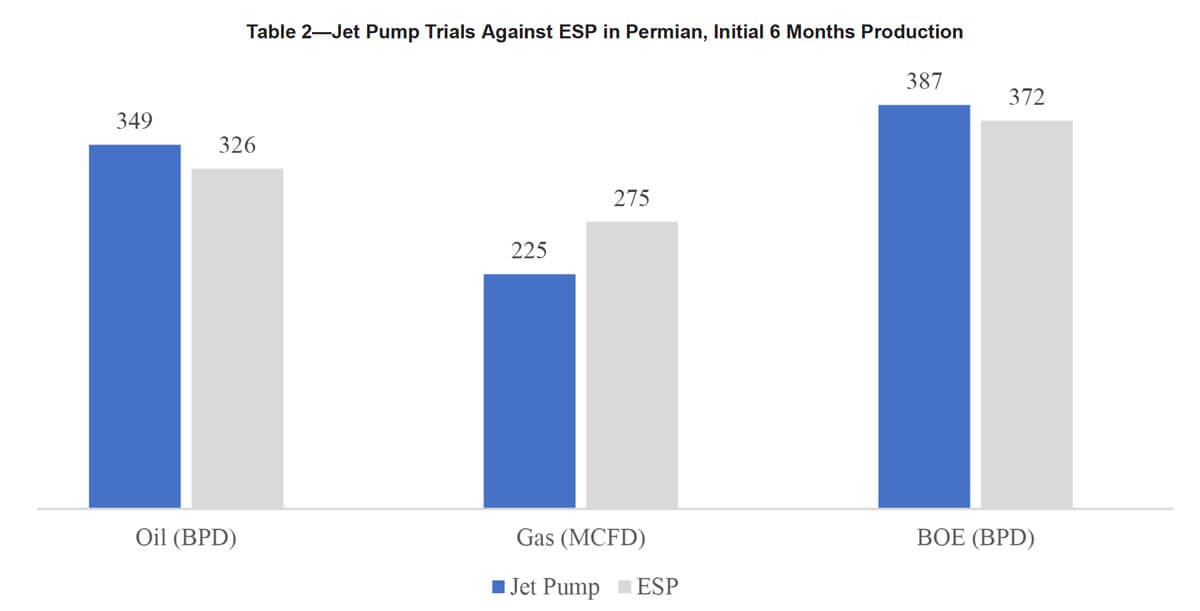

Hydraulic jet pumps were deployed to achieve artificial lift in two wells. In the first well, the hydraulic jet pump replaced a long stroke rod pumping unit, and average production data was compiled. This data compared the production average over a six-month time period of the rod pump, vs. a six-month time period using the hydraulic jet pump. In the second well, a hydraulic jet pump was installed in a newly horizontal fracked well, and an ESP was installed in a new adjacent well under very similar conditions; production rates and performance issues were compared.

Presentation of Data and Results

The results relating to the artificial lift performance of hydraulic jet pumps vs. rod pumps and ESPs in the two subject wells are summarized as follows:

Hydraulic Jet Pump Replaces Long Stroke Rod Pumping Unit in the Eagle Ford

Tight turns, long laterals, multiphase flow regimes and steep decline rates were among the distinct challenges of an unconventional well site located in the Eagle Ford. The well had pockets of predominantly dry gas, wet gas and oil, making rod pumps and ESPs impractical. The profile of the lateral also limited the type of artificial lift system that could provide optimum performance.

With the rod pump, the surface unit and downhole pump were operating at max capacity. Due to rod/tubing wear, the pump depth was limited to 8417’ Measured Depth (MD) (1 DEG). The six-month average production was 68.9 oil; 6.4 water; and 22 MCFPD. (Table 1) At least one intervention had been performed in the previous four months of operation.

The long stroke pumping unit was replaced by a hydraulic jet pump, installed and set at 8814’ MD (45 DEG). By setting the pump lower, the operator was able to increase recoverable reserves over other artificial lift options that have limited setting depths in horizontal and deviated wells. On the surface, an 80 hp electric powered Hydra-Cell seal-less diaphragm pump was set with an ASME code power fluid vessel. Only 45 hp was utilized to lift the well. Following the hydraulic jet pump installation, the average production for the following six months was 120 oil; 24 water; and 165 MCFPD.

Hydraulic jet pump handles heavy challenges in the Permian Basin

One Permian Basin operator who typically utilized ESP systems in its wells was faced with a unique operation issue. It needed a single form of artificial lift to carry the well from a virgin reservoir flow state into long term production, while having the ability to handle and produce solids with high gas production rates.

In May, 2016, a hydraulic jet pump was installed in a newly horizontal fracked well, and an ESP was installed in a new adjacent well under very similar conditions. Where the ESP installation experienced two failures that cost more than $300k in workover and equipment replacement, the jet pump experienced no failure, with downtime limited to quarterly service of the surface pump, including a change out of the mixing tube due to solids production. Due to the serviceability of the jet pump design, the technician was able to simply reverse circulate the pump from the well bore, change the worn mixing tube, and have the well back in production in 1-2 hours.

With the jet pump’s ability to set in the lateral section, it allowed the operator to take advantage of additional bottom hole pressure, with limited gas breakout. Over the first 6 months of production, the jet pump had significantly less maintenance cost and similar production to the ESP.

Gas Lift in Wilcox Formation Replaced with Hydraulic Jet Pump

A Wilcox formation well being produced by gas lift was facing economic and operational issues. The field, being gas deprived, was dependent on costly make up gas to fuel compressors and lift fluid from wells. Also, with the lack of electricity on location, the operator was limited in the types of artificial list they could test.

The client selected a jet pump rental system with a 180hp natural gas driven surface pump. Jet pumps can be used in remote locations such as this without electricity or infrastructure. The overall down hole and surface installation too less than two days, greatly minimizing well down time.

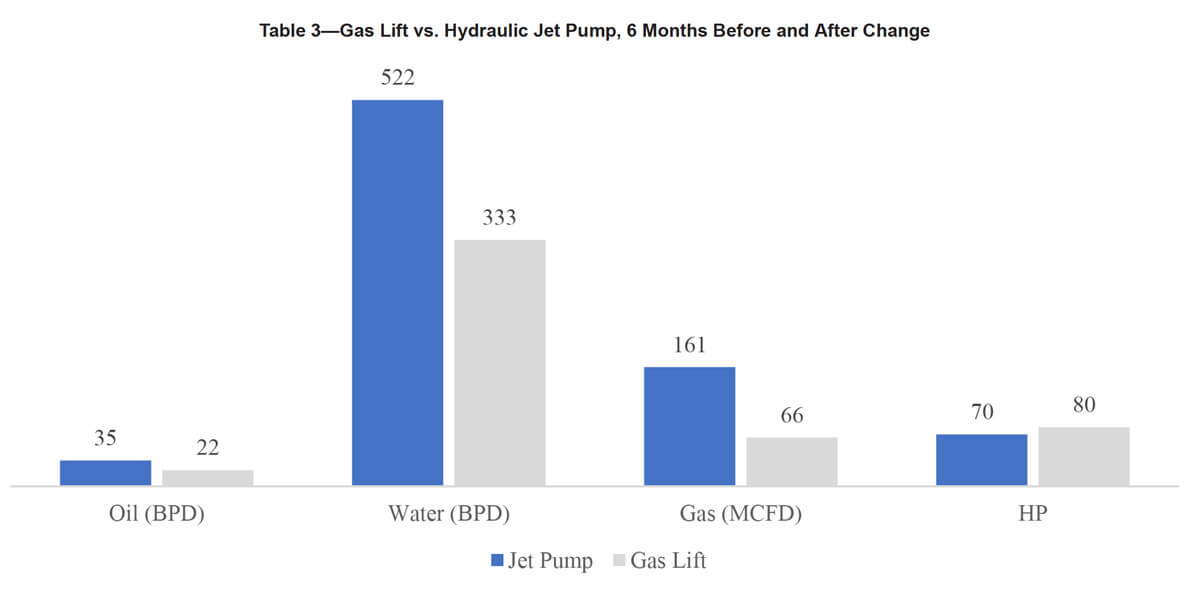

After the testing period, an electric 125 hp surface pump was installed for permanent production. The production increase (Table 3, Customer Data) justified the CAPEX of bringing electricity to site.

Conclusions

Hydraulic jet pumps are positioned to address the industry need for the most cost-effective and reliable lifting solutions in unconventional wells. Compared to rod pumps, electric submersible pumps and gas lift systems, hydraulic jet pumps can deliver better artificial lift performance at lower overall cost over the life of an unconventional well operation. The ability of hydraulic jet pumps to operate reliably at deeper depths, and in deviated wells, also provides significant advantages. With no moving parts, hydraulic jet pumps offer decreased risk of equipment failure from solids, allowing them to operate for years at a low risk of failure. More rugged and tolerant of abrasive and corrosive well fluids than other types of downhole lift systems, hydraulic jet pumps help operators avoid the need for numerous workovers that are typically required to change out lift systems over the life of the well. Operators can save considerable time and money by keeping a jet pump system in place until reservoir energy is significantly depleted.

References

Petrowiki/SPE International – Advantages and Disadvantages of Artificial Lift Systems

Railroad Commission of Texas Production Data Query System (PDQ)