The Tech-Flo TFC-ASC Filter System features VAF V-SeriesTM automatic self-cleaning screen filters that can be used wherever water flows to remove suspended solids. The Tech-Flo TFC-DSS Filter System utilizes materials for continuous flow pumping or filtration applications.

The Tech-Flo TFC-ASC Filter System uses the patented technology of the VAF V-SeriesTM automatic self-cleaning screen filters. The filters can be used wherever water flows and can remove suspended solids from 1500 to 10 micron. Individual filters and pre-assembled filtration systems are used in applications for Pre-Filtration of membrane, UV and other micro filtration technologies, as well as applications for industrial water reuse, SWD, fluid transfer, truck offloading, cooling towers, seawater, river intake water, well water, irrigation and many more.

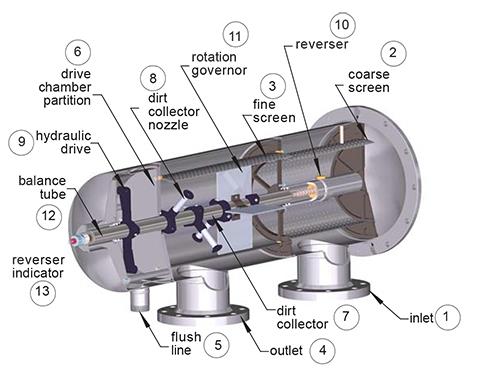

The V-Series filter bodies are manufactured in 316L stainless steel and are competitively priced. The stainless steel bodies also come with a 5-year warranty against body leaks of any kind. The patented Bi-directional Hydrodynamic Drive (BHD) design DOES NOT require electric motors, limit switches, gearboxes, or hydraulic pistons, thereby eliminating external shafts and seals. The cleaning cycle takes less than 15 seconds and does not interrupt the filtration process.

The Tech-Flo TFC-DSS Filter System utilizes two continuous flow simplex strainer baskets in unison, a piping manifold and isolation valves that are used in continuous flow pumping or filtration applications where the process cannot be shut down for cleaning. These applications include suction or inlet placement for hydraulic lift systems, SWD pumps, fluid transfer, commercial disposal facilities for pre injection and offloading, post well head filtration for “dirty wells” and much more. The filter pots can be cleaned out “on the fly” by isolating a single pot while the other pot is in use. By providing greater screen areas than a Y-strainer, with a simplex pot you optimize the total open area and minimize potential pressure loss through the baskets.

Tech-Flo offers the TFC-DSS Filter System in carbon steel and stainless material with pipe sizing from 2” up to 6”. Available in ANSI pressure ratings/flange sizes from 150 to 600. Filter baskets are available with screen sizes from 400 mesh (37 micron) up to 1/4” holes and all manufactured in SS material.