Tech-Flo’s jet pump is uniquely designed to allow for easy retrieval of the pump from straight well bores as well as deviated and horizontal wells, with no work over or wire line unit required.

Tech-Flo’s newly designed jet pump (patent pending) was developed to be a competitive means of artificial lift for all types of producing oil and gas wells. With the flexibility of the jet pump system, many operational issues that affect other types of artificial lift can be eliminated.

The unique design allows for easy retrieval of the pump from straight well bores as well as deviated and horizontal wells. Retrieval of the jet pump for repair or optimization is done by manipulation of the surface valves and reverse circulation of fluid, no work over or wire line unit is required.

Typical applications of the Tech-Flo jet pump include conventional oil and gas production, high volume frac unloading, gas well dewatering, well tests, slimhole well production, and producing wells with bad casing. The pump can also be run in conventional or reverse flow configuration.

| TFC 1.66 | 1” TO 2” IJ/Coil or 2.375 SSD/Cavity | Up to 1700 BPD | DD-G | 000-10 |

| TFC 2.20 | 1.5” to 2.375” or 2.875/3.5 SSD/Cavity | Up to 4000 BPD | AA-J | 00-12 |

| TFC 3.10 | 2” TO 4.5” or 4.5 SSD/Cavity | Up to 10000 BPD | AA-J | 00-16 |

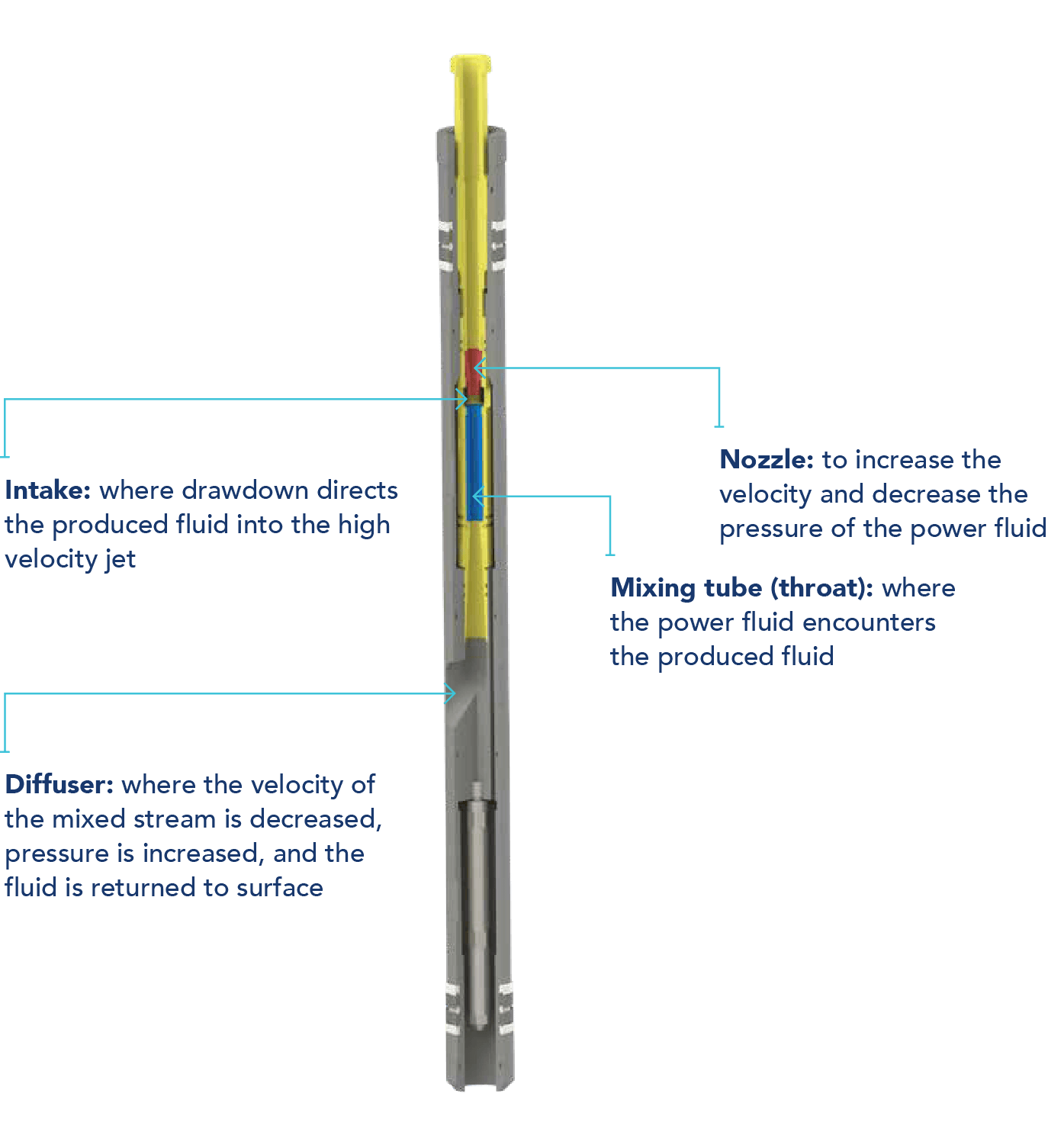

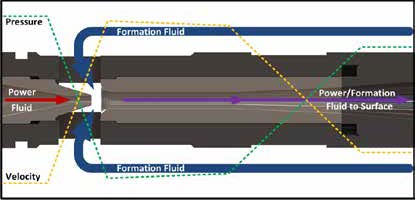

The Tech-Flo Jet Pump functions by utilizing the Venturi effect. The Venturi effect (shown below) is a special case of Bernoulli’s principle which states that as fluid flows through a pipe with a constriction in it (nozzle) the fluid must speed up in the restriction, reducing its pressure and producing a vacuum via the Bernoulli Effect. This vacuum is what brings formation fluids into the jet pump and to the surface.

The jet pump utilizes the momentum of one fluid to move another fluid.